The systemised guide to optimising your teams during the skilled labour shortage and the impending infrastructure boom.

The end of 2019, has seen the momentum of the infrastructure boom during the beginning of the year slow down and subcontractors have been scaling back their casual workforce to compensate for the downturn. Whilst other subcontractors are scrambling to find more work, leading subcontractors have been maximising this slow down to scale their operations and implement technology-enabled efficiencies in preparation for the infrastructure boom of 2020 and beyond.

Australia’s growing population continues to put unprecedented pressure on the maintenance backlogs of our major transport lines as well as required new infrastructure. Since 2015, over $123 billion has been invested in infrastructure work. With $200 billion still sitting in the pipeline for 2020-2023. To further stress the challenge ahead, Infrastructure Australia Chair, Julieanne Alroe emphasised that “projects across Australia are getting larger and increasingly complex, and will require new approaches if they are to be effectively delivered”. Alroe further highlighted that “our current tools are not well placed to deal with many of the new infrastructure problems we are facing in today’s rapidly changing environment…rapid technology change is fundamentally reshaping our day-to-day lives”.

Source: Macromonitor – Major Transport Projects August 2019

To add to the overwhelming challenges of complex projects, Australia has been suffering a severe skilled labour shortage, as businesses have struggled to cope against the increasing amount of projects across the country. The fundamental question is how do we do more with less?

Implement technology-enabled efficiencies

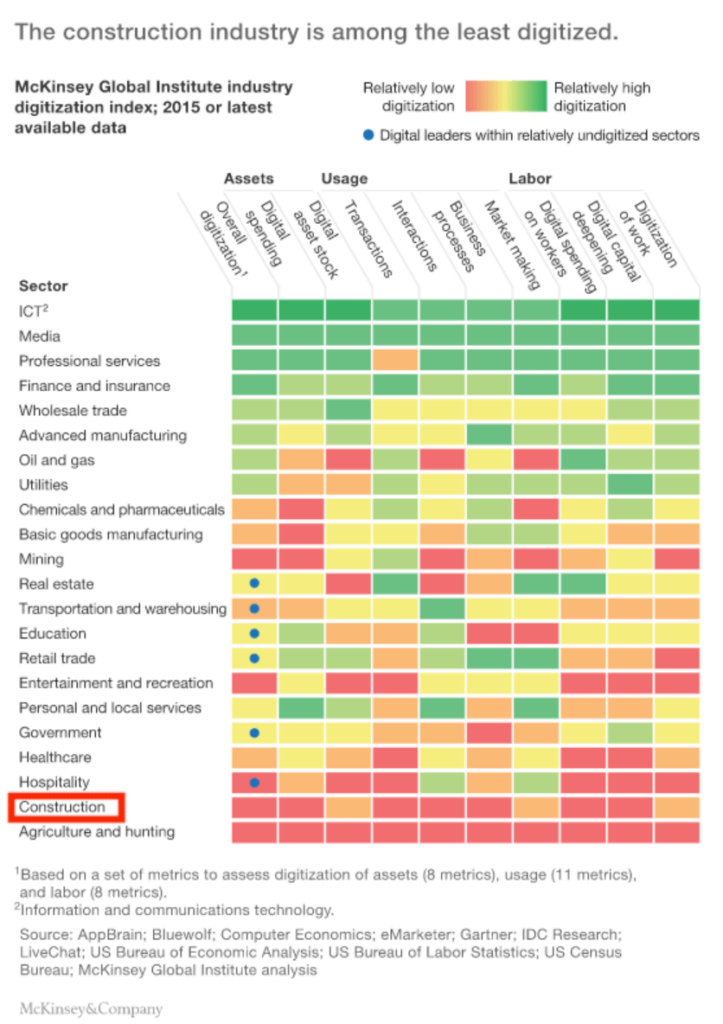

Despite the longevity of the industry and the billions of dollars invested in infrastructure work not only in Australia but globally, the construction industry remains one of the least digitised.

Many subcontractors are still relying on processes that were used in the 19th century. From machines that are crucial for civil projects to how they manage the safety and productivity of their teams on site. The likes of vacuum truck excavations (NDD) to excavators are being maintained by highly skilled staff with the most up to date tools. But their safety documentation, pre-start forms, site diaries, timesheets, dockets and materials capturing are done via paper. This rich data then needs to be re-entered and used for safety reporting, payments and tracking actuals against the budget. Due to the manual ways of capturing and reporting on this data, it is susceptible to weather conditions, human error, double handling and just getting misplaced or lost.

McKinsey and Company noted that the vast majority of projects are still being treated as one-off prototypes instead of a combination of highly repeatable processes that can be scaled and automated. Furthermore, large projects are taking 20% longer to finish and once completed are ending up 80% over budget.

This common occurrence is due to the lack of visibility subcontractors have into their business operations during the project. Learning where your resources are being under-utilised starts with micro-level data. From hours works, activities performed, materials used to where machines are sitting idle or due for maintenance. All this powerful data is sitting on paper, unable to be analysed by project managers because it can’t be aggregated in a meaningful manner, nor received in real-time for actionable plans.

The first step towards implementing technology-enabled efficiencies is taking the leap into the deep end and saying yes to worksite digitisation. There are many roadblocks to successfully implementing change, and moving from paper to digital can be quite a daunting task for a workforce, not familiar or attuned to technology like other industries. Ensuring buy-in from all key stakeholders starts with learning the why and then the how.

Why?

The infrastructure boom is coming and how businesses sustain a competitive advantage is proving more challenging. All subcontractors like to market their business as leaders in safety and delivering quality work. With the standard of delivering such works increasing due to more and more competitors paired with strict legislation reforms, subcontractors need a better way to manage their safety and quality. Implementing a digital solution to manage your operations, showcases how innovative your company is. In an industry, renowned for low tech adoption, a subcontracting business with a sophisticated digital system, already stands out from the crowd.

In addition, to the business development opportunities digitisation has for business, it also has many cost-effective bonuses which at the end of the day means you save time and money, so you can build more.

“We couldn’t have expanded the way we did without Assignar. We added 70 new employees since implementing the platform, but only one of them has an administrative role. If you have a person doing an administrative job in your office, you can probably get Assignar to do the same job.” – Duron Atlantic

How?

Three key pillars to help subcontractors prepare for the infrastructure boom during the skilled labour shortage include:

#1 – Operations software for efficiency, to meet project requirements and regulation compliance

#2 – Solid hiring and training plan (meet skilled labour demands)

#3 – Finance plan

In regards to the first step. Assignar is an Operations software built for civil contractors. Assignar’s Site Diary or Daily log captures all your day’s site timesheets, activities and approvals in one easy form that’s instantly transmitted back to the office. With Assignar’s Daily Log you can:

- Accurately capture your whole crew’s time on site

- Capture materials and consumables used

- Sub-contractor units captured and tracked for full supply chain visibility

- Capture units against site activities and their budget cost code

- Capture electronic signature for instant client-approval

- Boost productivity with any progress/updates/issues immediately communicated to the office.

Pairing a daily log with electronic safety forms and documentation enables communication efficiencies, particularly in the midst of an incident or near-miss. As well as managing urgent maintenance and allocating resources in a way that maximises their usage. In addition, Assignar is a data hub off all your worker’s competencies, licenses, certifications and permits.

Be efficient when scheduling out these resources to your projects. Assignar’s compliance rules allow you to configure standards set by your clients and the projects you work on. Assignar will automatically select the relevant resources based on the roles and asset configurations, which allows you to forecast better on if you have enough resources for existing and up and coming projects.

Once you have the tool to holistically capture your day to day operations, the next step is analysing that data in a meaningful manner. Actionable insights can be the difference between going over time and over budget, to maximising spend and coming out on top.

Don’t rely on project managers to work after hours and aggregate spreadsheets and field data collection. Give them the right tools so they can Track site production such as crew hours worked, asset utilisation and materials used. Manage delays and variations digitally and in real-time and keep track by having an audit log for claims you can reference back to your clients if disputes arise.

Assignar’s BI-360 module empowers users by giving them the insights into their operations and share that data in a regular cadence with key stakeholders. From competency matrix, resource utilisation reports to customisable dashboards.

Ultimately, a digital solution can bear the brunt of the skilled labour shortage during the infrastructure boom of 2020. As a sophisticated system paired with internal advocates becomes a catalyst for positive change in not only your business but within the industry.